Therefore the bend allowance added to the flange lengths is equal to the total flat.

Bend angle tolerance sheet metal.

Refer to the chart for values for folder as well as various press brake tooling combinations.

I agree but apperently there is no way to change the precision in solidworks other than overriding the text unless i am missing something.

Understanding the bend allowance and consequently the bend deduction of a part is a crucial first step to understanding how sheet metal parts are fabricated.

The bend allowance and bend deduction are two measures that relate the bent length of a piece of sheet metal to the flat length.

Well it can be with realistic tolerancing.

Why then do press brake operators still have so many tryout parts.

The science of sheet metal bending has proven formulas for bend allowances and bend deductions that account for material elongation for given materials.

The sheet metal bending height should be at least 2 times the thickness of the sheet metal plus the bending radius that is h 2t r.

Angle tolerances are typically denoted by x xx.

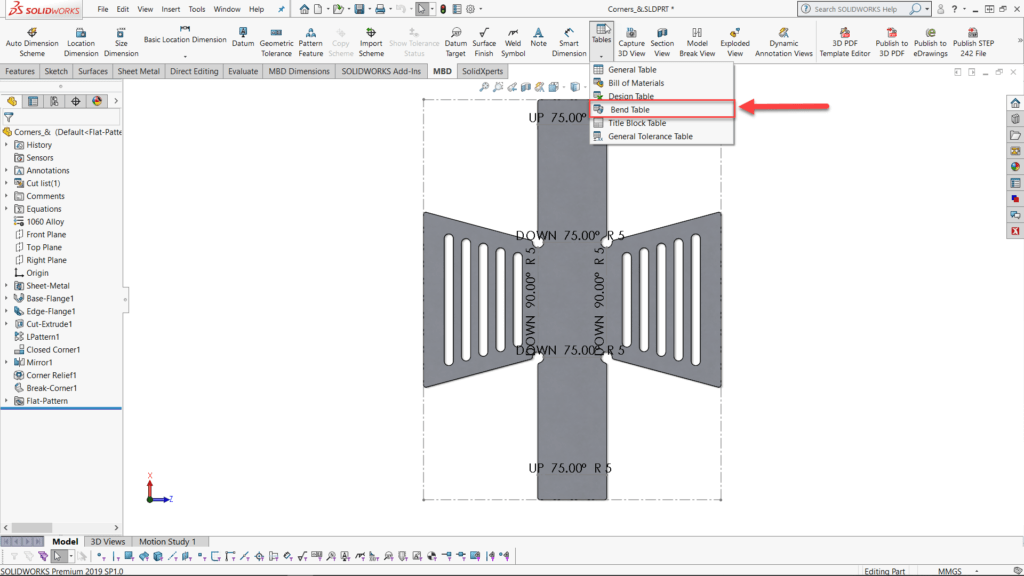

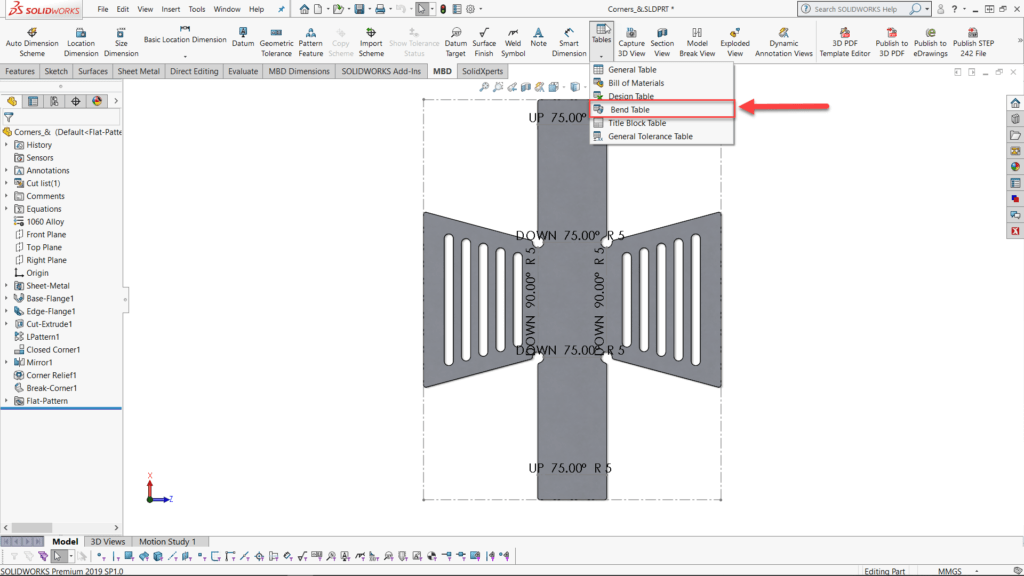

I have creates a drawing of a sheet metal part.

Thereby forming a certain angle and curvature shape.

Bending is a stamping process that uses pressure to force the material to plastically deform.

As this happens you gain a small amount of total length in your part.

Commonly used equipment include box and pan brakes brake presses and other specialized machine presses typical products that are made like this are boxes such as electrical enclosures and rectangular ductwork.

Why can t bending be simpler.

The diagram shows one such mechanism.

The extent of its elastic properties is controlled largely by the material s mechanical properties.

If your bend angle has a fair amount of angulararity tolerance then the metal may be controllable within a certain specified thickness and.

Geometry of tooling imposes a minimum bend dimension.

The tolerance specified by the engineer or designer tell the brake operator how much variation in the particular bend is allowable.

Sheet metal often viewed as a hard semi flexible medium is in fact an elastic type of material.

Bend length 0 010 0 25mm.

Bending is a manufacturing process that produces a v shape u shape or channel shape along a straight axis in ductile materials most commonly sheet metal.

Theoretically it shouldn t be complicated.

When the sheet metal is put through the process of bending the metal around the bend is deformed and stretched.

Press brake bend length 0 010 0 25mm per bend for controlled dimension.

Folder bend length 0 010 0 25mm per bend for controlled dimension.

Typically this information is located in the title block of a drawing.

Bend angle 1 degree.

This is rediculously tight tolerance for a bend angle and am being told to change it.

The bend notes default to two decimal point precision.